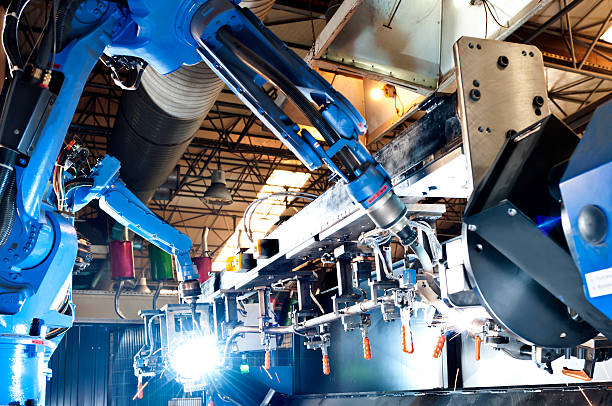

Heavy machinery is the backbone of operations for enterprises across numerous industries. Without it, everything comes to a complete stop. Proactively maintaining your heavy equipment is one of the best methods to reduce unplanned downtime, avert major workplace mishaps, and extend its life. Read on for some pointers from our experts on how to take care of your industrial equipment.

Pay attention to wear and tear

When cleaning your industrial equipment, spend some time examining the important components for signs of wear and tear. Regular use can lead some parts to wear out quickly and get damaged, which may go undetected. This is why you need to keep an eye out for any impending problems.

Furthermore, check your tires every day; it just takes a few minutes and might end up saving you more money on new tires. The objective is to fix minor faults before they worsen and impact your business’s supply chain.

Set up a maintenance schedule

Developing a regular maintenance schedule is one of the key measures in taking good care of your industrial equipment. It is necessary to regularly inspect every piece of equipment to look for any issues. That may include low coolant, missing or damaged teeth on the attachments’ cutting edges, poor tire inflation, low fluid levels, and leaky fluid lines.

Carrying out routine maintenance according to the manufacturer’s standards, such as replacing the oil or braking components, is necessary. By arranging repairs as soon as feasible, you can be sure that any issues with your industrial equipment won’t cause you to lose output.

Maintain access to spare parts

Consider keeping a few simple spare parts on hand to stay operational in an emergency. This could be something as basic as oil and filters for your pumps or something more intricate like new motors and belts from Kor Pak. Having the right parts available when a machine breaks down might make the difference between a quick and time-consuming repair.

It also makes it possible for maintenance crews to respond quickly to malfunctions. This cuts downtime and guarantees continuous, smooth operation.

Observe the manufacturer’s guide

Each piece of industrial equipment was designed to perform a certain function and to be utilized with a specific set of components and accessories. Operators can contribute to machine breakdowns in several ways, including:

- Using industrial equipment for tasks for which it was not intended

- Replacing any parts that are not suitable

- Using attachments that are not fitted correctly.

Maintaining your fleet correctly also means adhering to the manufacturer’s guidelines regarding equipment use and service.

Fix problems right away

If you find a problem with a machine or any of its safety features, fix it right away to prevent more damage. Doing so can assist you in avoiding future safety hazards and expensive repairs. The likelihood that an issue may deteriorate and lead to more serious problems increases with the time you wait to solve it. Preventive maintenance on a regular basis guarantees that your equipment will function well and stay in good shape for many years to come.

Final word

Follow these guidelines and be consistent in your maintenance practices to guarantee the effectiveness of industrial machinery.